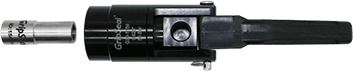

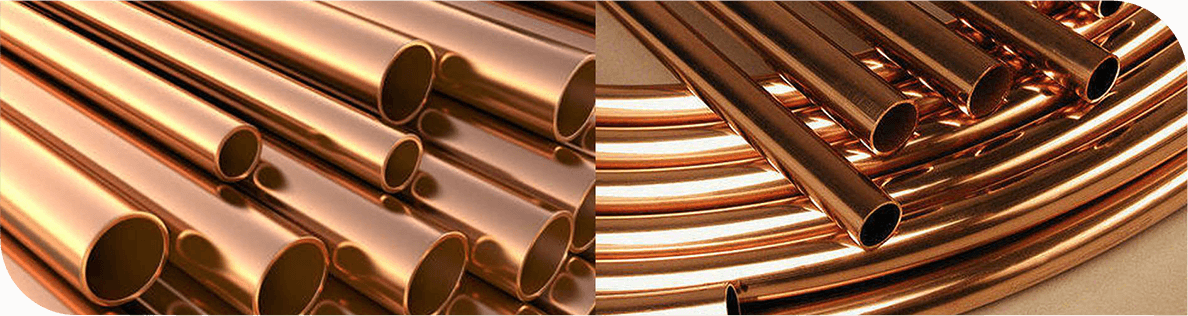

G30 series are high pressure application connectors, which are the optimal outer diameter connection solution for sealing all kinds of copper, steel and aluminum tubes, extensively applied in refrigeration and new energy industries, such as heat exchangers, pressure vessels,instruments,meters, motor controller cooling plates, etc.

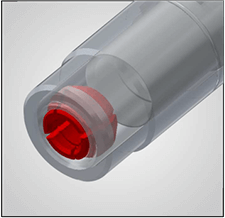

The sealing force is strengthened with the increase of test pressure

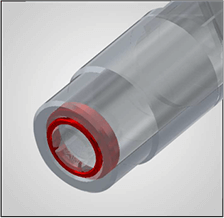

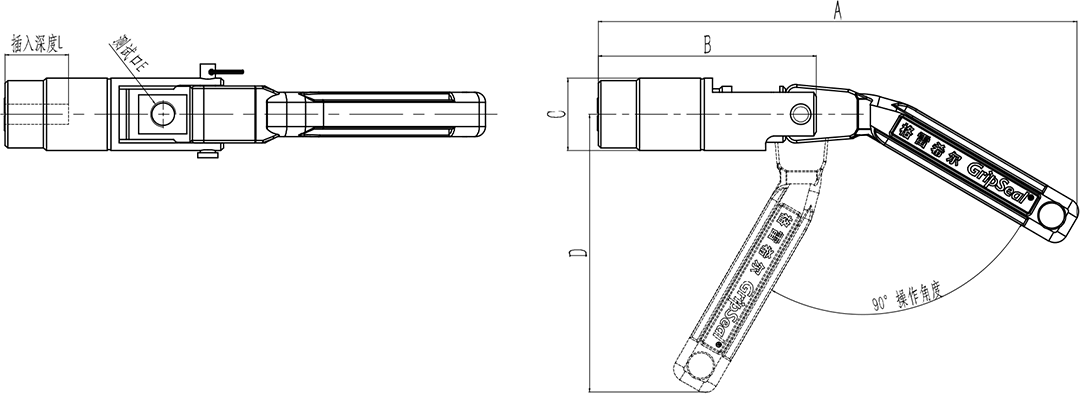

The test tube is inserted into the sealing hole at the front of the connector, folding the handle by 90° to achieve a sealed connection

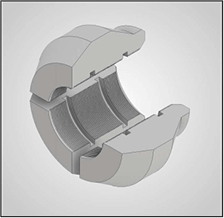

The surface of the collet is covered with engraved lines to increase the force area and provide higher gripping force, high hardness dowels are available to clamp stainless steel and mild steel

Standard BSPT1/8 or 1/4 threaded hole on the side, more suitable for international application scenarios

Once the test air pressure is completely removed, the handle will be folded back to the original position and the sealing effect will disappear to achieve safe disconnection

Display

G30 Series connectors included 7 types of British models, 8 types of metric models, satisfying the sealing range of 6 mm -22.23 mm

High Hardness Locking collets: Featuring locking collets that firmly clamp the outer wall of the tubing and increase the upper limit of test pressure

Horizontal Pattern Feature: Locking jaws are covered with tiny stripes engraved line to increase the force area and provide a firmer grip.

Automatic Repositioning: Allowing effortless operation, reducing the risk of jamming and raising operational efficiency

Nylon Handle: Ergonomic design, more comfortable for operation

BSPT terminationport:In line with international standards, commonly adopted, related accessories are easily available

| Max operation pressure | From Vacuum to 70 Bar |

| Sealing range | 6mm ~ 20mm |

| Minimizeinsert depth | 25mm |

| Termination port | ZG1/8 or ZG1/4 |

| Material of main body | Aluminum alloy or stainless steel |

| Main seal | Fluororubber |

| Internal seal | Buna-N |

| Pilot pressure | 4-6 Bar |

| Operation temperature | -20°C-120°C |

| Handle | Nylon |

Make connections easier

Inserting the test piece into the test port of the connector

Inserting the test piece into the bottom of the test hole

Folding the handle, where the test piece is locked in the test hole to complete the sealing

Processing tube seal testing

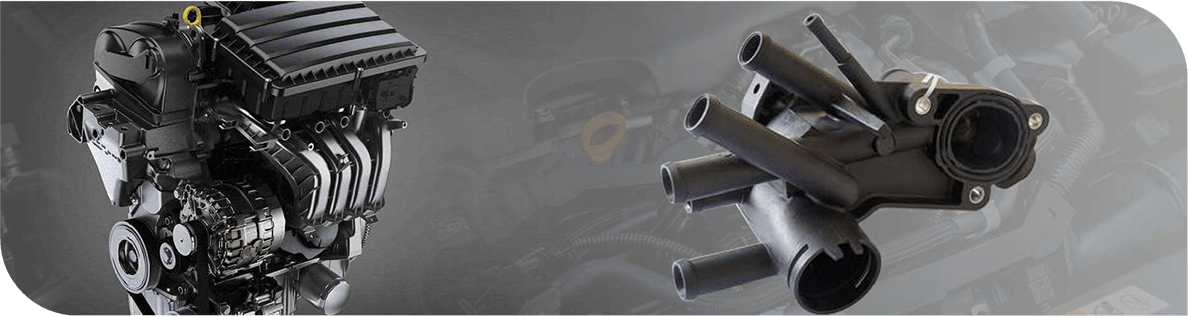

Air conditioner radiator test

Engine water-cooling channel testing

| Part Number | Sealing Range(mm)±0.25 | Maximum pressure | Flow diamete | Dim A | Dim B | Dim C | Dim D | Test port E | Dim L | Body material | Seals Material | Main Seals Package |

| G30-0063 | 6.35 | 70 Bar | 7 | 193 | 89 | 31 | 109.5 | ZG1/8 | 25 | Aluminum alloy | Viton rubber | SG300063 |

| G30-0079 | 7.92 | SG300079 | ||||||||||

| G30-0095 | 9.52 | SG300095 | ||||||||||

| G30-0127 | 12.7 | SG300127 | ||||||||||

| G30-1159 | 15.88 | 10 | 40 | ZG1/4 | SG301159 | |||||||

| G30-1190 | 19.05 | SG301190 |

| Part Number | Sealing Range(mm)±0.25 | Maximum pressure | Flow diamete | Dim A | Dim B | Dim C | Dim D | Test port E | Dim L | Body material | Seals Material | Main Seals Package |

| G30-0060 | 6 | 70 Bar | 7 | 193 | 89 | 31 | 109.5 | ZG1/8 | 25 | Aluminum alloy | Viton rubber | SG300060 |

| G30-0080 | 8 | SG300080 | ||||||||||

| G30-0100 | 10 | SG300100 | ||||||||||

| G30-0120 | 12 | SG300120 | ||||||||||

| G30-1140 | 14 | 10 | 40 | ZG1/4 | SG301140 | |||||||

| G30-1160 | 16 | SG301160 | ||||||||||

| G30-1180 | 18 | SG301180 |