The G15 series pneumatic quick seal connector utilizes air pressure to inflate the seal and create an internal air tight connection with virtually any type of tube, which is ideal for high volume automated production testing.

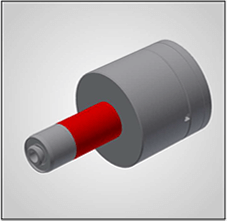

Achieving the internal seal by pushing the built-in piston and compressing the seals

With the 2 fixing holes at the bottom , This connector can be mounted to on any actuator,enabling automated operation with precision and reliability

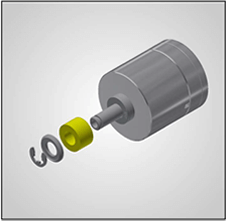

Reduce the intermediate part, improve the sealing and keep flow high

Build-in stroke limiter, Limit the maximum position of the piston, Prevent the sealing ring from falling out due to overload

G15 series quick connectors range from 0 to BG5, which can accommodate ID from 8.5mm to 44mm.

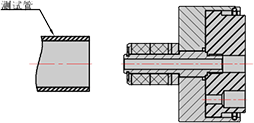

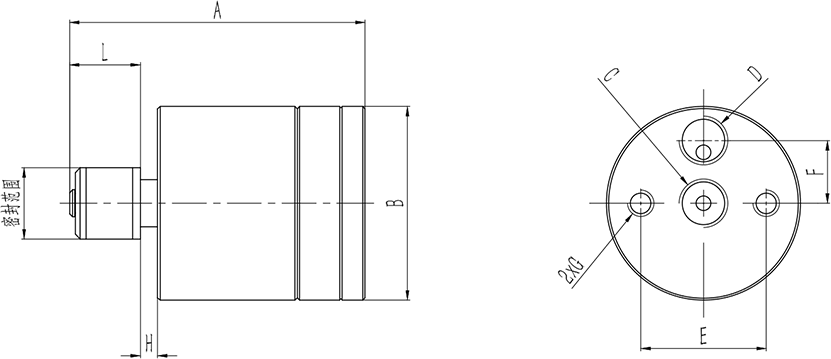

Main body display

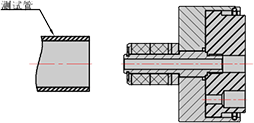

Insert the test tube into test port of the G15 series, and secure the test tube and connector.

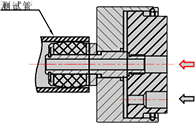

Introduce pilot pressure to pilot port. The seal is squeezed, creating expansion, which in turn clings to outer wall of test tube. In result, a leak tight seal is formed.

a. Filling the test port with test medium upon the formation of the seal (such as compressed air, test fluid, etc.)

b. After the test is completed, release the inner test pressure to atmospheric pressure, then remove the pilot pressure, the seal is no longer be squeezed, the seal connection release the test tube.

Once the above operation is accomplished, the test tube can be removed from the connector safely.

Pneumatic Driven: Reliable sealing & easy operation

Customization: Allowing flexibility in clamping position to avoid interference

Quick Seals Replacement: Simple maintenance & extended service life

Compact Size: No operating space needed, which can be positioned anywhere in the fixture

Automatic operation: Higher efficiency & more consistent test results

| Max operation pressure | From Vacuum to 8 Bar |

| Sealing range | Refer to specification sheet |

| Minimizeinsert depth | BG1, BG2: 15mm BG3, BG4: 30mm |

| Termination port | G1/8、 G1/4, G1/2 |

| Material of main body | Aluminum alloy or stainless steel |

| Main seal | Neoprene/silicone |

| Internal seal | Buna-N |

| Pilot pressure | 4-6 Bar |

| Operation temperature | -20°C-120°C |

The G15 system is designed to create a leak-free internal connection for a wide range of fittings by injecting drive pressure into the tail drive hole and forcing the piston forward, thereby squeezing the seal at the front end.G15 connectors are the perfect choice for high-volume automated production applications.

Cooling tube in electric motor

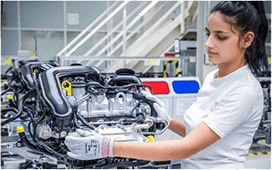

Engine assembly test

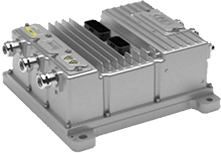

Motor control unit

| Model NO. | Sealing Range | Dim A | Dim B | Dim C | Dim D | Dim E | Dim F | Dim G | Dim L | Main Seals Package |

| G15-0080 | 8.5 – 9.5 | 50.4 | 33.5 | M5 | M5 | 20.3 | 10.0 | M5 | 12.2 | SG150080 |

| G15-0085 | 9.5 – 10.5 | SG150085 | ||||||||

| G15-1100 | 10.5 – 11.5 | 61.8 | 40.0 | G1/8 | G1/8 | 25.9 | 13.0 | M6 | 14.5 | SG151100 |

| G15-1110 | 11.5 – 12.5 | SG151110 | ||||||||

| G15-1120 | 12.5 – 13.5 | SG151120 | ||||||||

| G15-1130 | 13.5 – 14.5 | SG151130 | ||||||||

| G15-1140 | 14.5 – 15.5 | SG151140 | ||||||||

| G15-1150 | 15.5 – 17.0 | SG151150 | ||||||||

| G15-2160 | 17.0 – 18.0 | 61.8 | 40.0 | G1/8 | G1/8 | 25.9 | 13.0 | M6 | 14.5 | SG152160 |

| G15-2170 | 18.0 – 19.0 | SG152170 | ||||||||

| G15-2180 | 19.0 – 20.0 | SG152180 | ||||||||

| G15-2190 | 20.0 – 21.0 | SG152190 | ||||||||

| G15-2200 | 21.0 – 22.0 | SG152200 | ||||||||

| G15-2210 | 22.0 – 23.0 | SG152210 | ||||||||

| G15-3220 | 23.0 – 24.0 | 63.6 | 60.0 | G1/8 | G1/8 | 40.6 | 18.3 | M6 | 24.5 | SG153220 |

| G15-3230 | 24.0 – 25.0 | SG153230 | ||||||||

| G15-3240 | 25.0 – 26.0 | SG153240 | ||||||||

| G15-3250 | 26.0 – 27.0 | SG153250 | ||||||||

| G15-3260 | 27.0 – 28.0 | SG153260 | ||||||||

| G15-3270 | 28.0 – 29.0 | SG153270 | ||||||||

| G15-4280 | 29.0 – 30.0 | 63.6 | 60.0 | G1/8 | G1/8 | 40.6 | 18.3 | M6 | 24.5 | SG154280 |

| G15-4290 | 30.0 – 31.0 | SG154290 | ||||||||

| G15-4300 | 31.0 – 32.0 | SG154300 | ||||||||

| G15-4310 | 32.0 – 33.0 | SG154310 | ||||||||

| G15-4320 | 33.0 – 34.0 | SG154320 | ||||||||

| G15-4330 | 34.0 – 35.0 | SG154330 | ||||||||

| G15-5340 | 35.0 – 38.0 | 93.5 | 88.7 | G3/8 | G1/8 | 58.7 | 29.5 | M6 | 24.5 | SG155340 |

| G15-5370 | 38.0 – 41.0 | SG155370 | ||||||||

| G15-5400 | 41.0 – 44.0 | SG155400 |

| Model NO. | Sealing Range | Dim A | Dim B | Dim C | Dim D | Dim E | Dim F | Dim G | Dim L | Main Seals Package |

| G15RC-0080 | 8.5 – 9.5 | 50.4 | 33.5 | M5 | M5 | 20.3 | 10.2 | M5 | 12.2 | SG15-0080 |

| G15RC-0085 | 9.5 – 10.5 | SG15-0085 | ||||||||

| G15RC-1100 | 10.5 – 11.5 | 61.8 | 40.0 | RC1/8 | RC1/8 | 25.9 | 13.0 | M6 | 14.5 | SG15-1100 |

| G15RC-1110 | 11.5 – 12.5 | SG15-1110 | ||||||||

| G15RC-1120 | 12.5 – 13.5 | SG15-1120 | ||||||||

| G15RC-1130 | 13.5 – 14.5 | SG15-1130 | ||||||||

| G15RC-1140 | 14.5 – 15.5 | SG15-1140 | ||||||||

| G15RC-1150 | 15.5 – 17.0 | SG15-1150 | ||||||||

| G15RC-2160 | 17.0 – 18.0 | 61.8 | 40.0 | RC1/8 | RC1/8 | 25.9 | 13.0 | M6 | 14.5 | SG15-2160 |

| G15RC-2170 | 18.0 – 19.0 | SG15-2170 | ||||||||

| G15RC-2180 | 19.0 – 20.0 | SG15-2180 | ||||||||

| G15RC-2190 | 20.0 – 21.0 | SG15-2190 | ||||||||

| G15RC-2200 | 21.0 – 22.0 | SG15-2200 | ||||||||

| G15RC-2210 | 22.0 – 23.0 | SG15-2210 | ||||||||

| G15RC-3220 | 23.0 – 24.0 | 63.6 | 60.0 | RC1/4 | RC1/8 | 40.6 | 18.3 | M6 | 24.5 | SG15-3220 |

| G15RC-3230 | 24.0 – 25.0 | SG15-3230 | ||||||||

| G15RC-3240 | 25.0 – 26.0 | SG15-3240 | ||||||||

| G15RC-3250 | 26.0 – 27.0 | SG15-3250 | ||||||||

| G15RC-3260 | 27.0 – 28.0 | SG15-3260 | ||||||||

| G15RC-3270 | 28.0 – 29.0 | SG15-3270 | ||||||||

| G15RC-4280 | 29.0 – 30.0 | 63.6 | 60.0 | RC1/4 | RC1/8 | 40.6 | 18.3 | M6 | 24.5 | SG15-4280 |

| G15RC-4290 | 30.0 – 31.0 | SG15-4290 | ||||||||

| G15RC-4300 | 31.0 – 32.0 | SG15-4300 | ||||||||

| G15RC-4310 | 32.0 – 33.0 | SG15-4310 | ||||||||

| G15RC-4320 | 33.0 – 34.0 | SG15-4320 | ||||||||

| G15RC-4330 | 34.0 – 35.0 | SG15-4330 | ||||||||

| G15RC-1120-250* | 12.0 – 13.0 | 86.8 | 40.0 | RC1/8 | RC1/8 | 25.9 | 13.0 | M6 | 14.5 | SG15-1120 |

| G15RC-2180-500* | 18.0 – 19.0 | 111.8 | SG15-2180 | |||||||

| G15RC-3260-750* | 26.0 – 27.0 | 138.6 | 60.0 | RC1/4 | RC1/8 | 40.6 | 18.3 | M6 | 24.5 | SG15-3260 |

| G15RC-4280-500* | 28.0 – 29.0 | 113.6 | SG15-4280 |